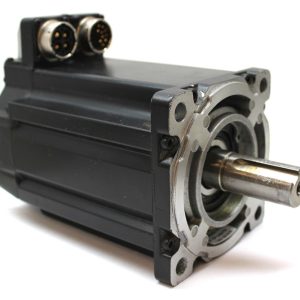

Allen Bradley Servo Motor Repair

Request Repair via below Chat with us or Call us @ 1-888-932-9183. Once we receive the request our Team members will call you to schedule a repair.

- Allen Bradley Servo motors are widely used in industrial automation, robotics, CNC machinery, and various other applications that require precise control of position, speed, and torque. However, like any other electromechanical device, servo motors are subject to wear and tear, which can lead to performance degradation or failure. In such cases, servo motor repair becomes necessary to restore the motor’s functionality and extend its service life.

- This guide will provide an overview of the servo motor repair process, common issues, and essential considerations.

- Allen Bradley Servo Motor Repair is a critical process that ensures the reliable and precise operation of industrial automation systems, robotics, and other applications that rely on servo technology. By addressing issues promptly and following the appropriate repair procedures, the lifespan of servo motors can be extended, minimizing downtime and maximizing productivity.

Bearing Failure: Bearings are critical components that support the motor shaft and allow smooth rotation. Worn or damaged bearings can cause excessive noise, vibration, and premature motor failure.

Encoder/Resolver Failure: Allen Bradley Servo motor rely on feedback devices, such as encoders or resolvers, to provide accurate position and speed information. Failures in these components can result in positioning errors or loss of control.

Winding Insulation Breakdown: The insulation surrounding the motor windings can degrade due to factors such as heat, moisture, or electrical stress, leading to short circuits or grounding issues.

Brake Failure: Many servo motors incorporate brakes to hold the motor shaft in position when power is removed. Brake failures can cause safety issues or positioning errors.

Contamination: Exposure to dust, debris, or liquids can cause damage to internal components, leading to reduced performance or premature failure.

Diagnosis: Before any repairs, a thorough diagnosis is essential to identify the root cause of the problem. This typically involves visual inspections, electrical testing, and evaluating the motor’s performance under various operating conditions.

Disassembly: If the problem requires internal repairs, the servo motor will need to be disassembled. This process involves removing the casing, separating the rotor and stator, and carefully handling the internal components.

Inspection and Cleaning: Once disassembled, all components must be thoroughly inspected for wear, damage, or contamination. Cleaning is crucial to remove any debris or residue that could cause further issues.

Component Replacement: Depending on the extent of the damage, individual components such as bearings, encoders/resolvers, windings, or brakes may need to be replaced with new or refurbished parts.

Reassembly: After replacing or repairing the necessary components, the Allen Bradley servo motor must be carefully reassembled, following the manufacturer’s specifications and torque requirements.

Testing and Calibration: Before reinstallation, the repaired Allen Bradley servo motor should undergo comprehensive testing and calibration to ensure proper operation, positioning accuracy, and torque output.

Reinstallation: Finally, the repaired or replaced servo motor is reinstalled into the system, and all connections, alignments, and configurations are checked and adjusted as needed.

- Accu Electric Professional Expertise: Servo motor repair often requires specialized knowledge, tools, and equipment. It’s generally recommended to seek the services of a qualified servo repair technician or facility with experience in the relevant industry.

- Original Equipment Manufacturer (OEM) Parts: Using genuine OEM parts or high-quality replacements is crucial to ensure compatibility, performance, and longevity.

- Feedback Device Repair and Alignment: Proper repair and alignment of feedback devices, such as encoders or resolvers, are critical for maintaining positioning accuracy and control.

- Environmental Considerations: Servo motors used in harsh or demanding environments may require additional protection or specialized repair procedures to ensure long-term reliability.

- Preventive Maintenance: Regular maintenance, including cleaning, lubrication, and inspections, can help extend the life of servo motors and prevent costly repairs or downtime.

Allen Bradley Servo Motor Repaired and Tested

Why to Trust Accu Global?

Trust Accu Global for a:

- Quick, free quote

- Over 30+ years of experience in the Industry

- Expert, full repair service

- As little as 24-48 hour turn around

- Rush Service if needed

- 80,000 sq. foot Tech Center

We look forward to the opportunity to work with you – call us 24 hours a day at 1.888.932.9183 or CONTACT US for a free quote.